The logistics situation has deteriorated seriously and many sellers have been forced to change their delivery plans!

The docks are congested, delivery companies are refusing to accept parcels, and UPS, FedEx, and USPS have all issued delay notices. Under the double blow of the snowstorm and the epidemic in the United States, the poor logistics and orders have made it seem that every cross-border e-commerce person is struggling.

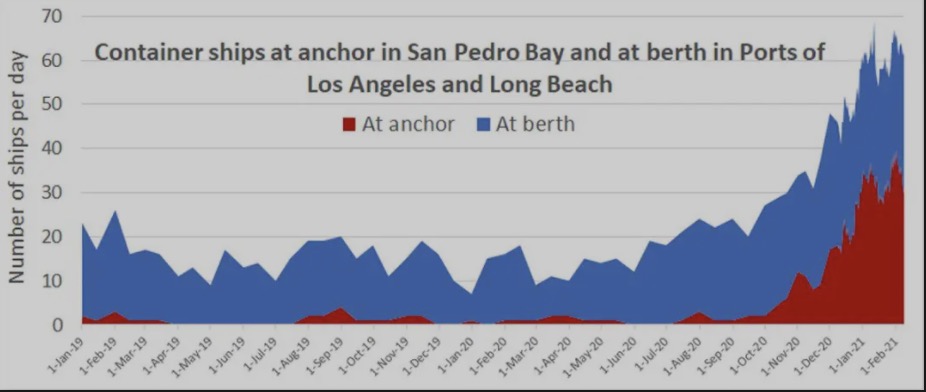

Video footage released recently by the U.S. Coast Guard shows how extreme traffic congestion has become at the ports of Los Angeles and Long Beach.The image below shows a large fleet of container ships scattered at anchor in San Pedro Bay, California.

(Photo/AmericanShipper)

(Video/AmericanShipper)

Data shows that container ship traffic congestion in California ports has not really eased. There are currently 63 container ships in Los Angeles and Long Beach, and 32 container ships are waiting for berths at anchorage. The Port of Los Angeles recently disclosed the number of days container ships are berthed through its platform The Signal.The figures confirm that some ships spend almost as much time at anchor as they do crossing the Pacific.

The waiting time for ships to berth is longer, and the shipping time is as long as 40 days

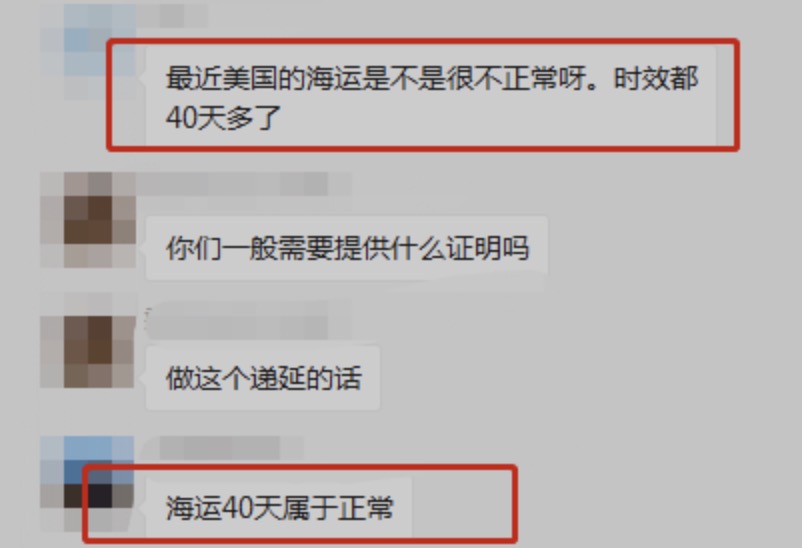

In the logistics exchange group,A freight forwarder said: "It is normal for US sea freight to be picked up or arrive at the port in about 40 days." Now with the impact of the US blizzard on terminal delivery, it may take longer than 40 days to successfully deliver the goods to customers.

Data shows that the number of anchored container ships began to increase in July last year, and the number of anchored ships has been rising steadily since November.

By the end of last year, the number of container ships at berth had grown to 30. Since then, it has remained between the 20s and 40. Meanwhile, the number of ships berthed in Los Angeles and Long Beach has remained in the 20s and 30s.“We seem to have settled into a new normal of about 30 container ships per day waiting in line,” said Kip Louttit, executive director of the Southern California Marine Exchange. “I don’t know if that’s going to continue.”

In response, the freight forwarder said: "There will be some delays in berthing at the port, so sellers should still change their stocking plans in advance."

"The port is quite crowded at the moment," said Hapag-Lloyd CEO Rolf Haben-Janssen, while sharing a picture.The image is filled with dots representing boats waiting to be anchored in San Pedro Bay.

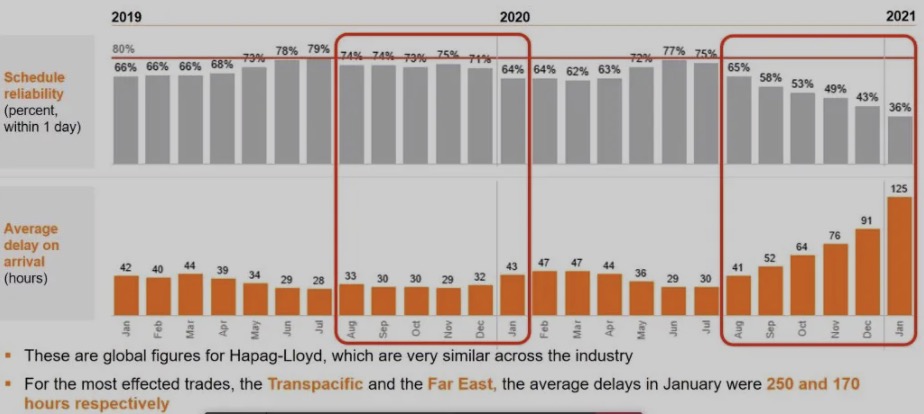

"Hapag-Lloyd's average arrival delay increased from 43 hours in January 2020 to 125 hours this year," Janssen said. "These are levels we have rarely seen before."

It is understood that there were nearly 300,000 TEUs (equivalent to 20 feet) waiting to be unloaded in January, and the situation has not improved in February, with congestion and ships waiting to be unloaded piling up.

A surge in U.S. imports, coupled with labor shortages caused by COVID outbreaks at ports, has led to delays in unloading ships and returning empty containers to Asia.

Shipping boom fuels $10 billion spree for new container ships

Some of the world’s largest container shipping companies are ordering new ships amid surging demand for ocean shipping, creating a huge business opportunity for Asian shipyards. The number of container ships on order rose by 23 to 201 last week, the biggest weekly gain in two years, according to IHS Markit data compiled by Bloomberg.

"Further order confirmations are expected in the coming days and weeks, and we expect to confirm more than $10 billion in containership newbuilding contracts from the fourth quarter of 2020 to the first quarter of 2021," said Gordon, an analyst at Shinyoung Securities Co.

In addition, in order to solve the problem of "scarcity of containers", many shipping companies began to order large quantities of containers, which brought explosive growth to Chinese container manufacturing companies. Some container companies are even stepping up production to meet orders during the Spring Festival.

CCTV reporters interviewed a container manufacturing company in Fujian. A worker said: "When I first joined the company, my monthly salary was about 7,000 yuan. Now my monthly income is over 10,000 yuan. In the six months since I joined the company, I have more and more colleagues. The number of front-line employees has increased from more than 300 to more than 500 now, and the company is still recruiting."

The head of a container company in Fujian told CCTV reporters that since the fourth quarter of last year, 40-foot containers for export have become the main type of order sales.He said that the current orders are scheduled to be produced until June this year, and customers are in a hurry to get boxes. Every time a box is finished and inspected by the customs, it is basically sent directly to the port for customers to use.In order to cope with the current shortage of containers, local customs has taken some measures to improve customs clearance efficiency.

The above content comes from the WeChat public account of "Cross-border Rhino"